"BASICS of Boatbuilding CLOTHS”

.... what they look like, and what they are used for.

This article is for those who are just starting out in boatbuilding and who might be overwhelmed with all the cloth options seen & talked about. Once you have this clear, you should be better able to make the right choices for whatever reinforcing you are needing.

(Although I will start with FIBERGLASS (FG), other

ADDED 2024: A note about 'the K factor' of strands.

All woven cloths are made using strands which are then woven. These strands are make up from super-fine filaments. If we look at currently available (2024) carbon fiber cloths, their strands vary from 1K (1000 filaments), through 2K, 3K, 6K, 12K to 24K for which a strand now contains 24,000 filaments. The denser the strand, the stronger and stiffer the cloth will be. For normal boat use, 3K and 6K are the most common, with very occasional use of 12K for some special component. Typically, 12-24K are use for aerospace, military and space projects. Using too low a K-number may not be strong enough for a highly stressed part, but using too high a K-number can reduce the long term endurance of a part, as it loses flexibility and impact resistance. Its 'a judgement call' to match the preferred K-grade with the required service needs. But 3K-6K is typically the practical range for most marine use.

FIBERGLASS comes in different weaves, each designed for different uses. The basic cloth is what we call a Bi-Directional one .. with roughly equal strands both up & down and across the cloth, each interwoven. This is often sold as ‘Boat Cloth’ as it’s most commonly used for sheathing plywood or even a planked wood hull. As fiberglass has greater elasticity than wood, it can accept the normal expansion of wood without being overstressed.

When purchasing cloth, you will need to specify not only the type of

Boat Cloth is available in very light weaves (for models etc), but typically the lightest we use for small boat sheathing is 4 oz, with 6oz generally being the minimum for underwater surfaces.

Adding such a cloth is a good way to guarantee and control an even thickness of epoxy over the wood surface. It also adds some strength, toughness

Any interior glassing AFTERwards is full of problems. You can be sure that any void will ultimately find water in it and as it can no longer dry out, rot will start BEHIND the glass in such a case. For this reason, a bad fiberglass job (passing over structure and framing), is FAR worse

All inside (concave) corners first need fillings of epoxy putty (made to ‘a consistency of creamy peanut butter’ by adding one of various types of filler powder to catalyzed epoxy resin) and formed smoothly with a plastic squeegee, shaped with a suitable radius that may vary from 5mm up to even 30mm for a high strength joint.

All exterior (convex) corners need to be radiused off with at least a 5mm

A heavier boat may need a sheathing boat cloth of 12 oz or more, but this is more

Because the weave is fairly even and flat, this Bi-Directional boat cloth is also sometimes used as the final layer over composite sandwich hulls or other surfaces requiring lightweight protection.

It's worth adding a note here on Elasticity. We often see it written that "it's worthless to add Fiberglass over wood as it's far more elastic than wood so offers no advantage but just adds weight". Here's my personal take on this. Yes, it does add weight and therefore its use needs to be measured against the advantages of adding it for each specific area of a boat. But FG adds abrasion resistance and also helps to control the thickness of the resin layer. But here is where I may disagree with some. My tests show that it can also add some stiffness and here I think is why. The figures for Elasticity are based on how much stretch the material can endure at the point of failure. This is certainly significantly higher for fiberglass than for wood, but there is STILL some resistance to flexing offered by the FG at the lower level, where the bare plywood would normally fail. Yes, the full resistance of the fiberglass will seldom be reached when the plywood fails, but on the curve of stiffness vs load, the fiberglass will still add 'some percentage' to the panel stiffness. There is also a gain in stiffness due to the increase in thickness from the sheathing. Stiffness goes up by the Cube of the thickness, so only a 3% gain in thickness theoretically gives 9.3% increase in stiffness (assuming the same material). Stresses are also higher at the outer fibers of any panel so that's where failure will first occur. Having an elastic boundary layer there is not such a bad thing, even 'if' the wood were to fail first. And finally, fiberglass with cured resin, is no longer as flexible as the cloth alone. It's relatively brittle in fact, as when encapsulated in resin, its seemingly high Modulus of Elasticity is typically chopped by about 65%, according to test figures I've seen using vinylester (epoxy similar), from a federal university in Rio. So overall, its not quite as simple as the opening statement implies.

Make your own tests if needed. Just sheath some plywood and cut 250 x 50 strips in different directions and compare this with unsheathed plywood. You just have to decide if the improved surface resistance and moderate gain in stiffness is worth the extra weight. In some locations, I think it is.

Another weave that is being used more and more is called UNI or UNI-Directional, where the majority of fibers lay in ONE direction. Of course, something is needed to hold these fibers together so some

The reason UNI directional cloth is used more and more is that engineers now do more calculations, recognizing that fibers must be oriented directly in line with predictable stress to be fully effective, and when pre-woven cloths are used, they sacrifice that ideal far too often. To make this even more effective, strands of a fiber (FG or CF) are often bundled together in what we call

One place that UNIdirectional cloth is used, is as a binder around and across a boat built with wood strips. While the wood strips give good longitudinal strength to a boat hull, they have little strength across the boat as there are seldom any transverse frames in a stripped boat. To compensate for this, UNI cloth is laid from gunwale to gunwale perpendicular to the wood grain, both inside and out, effectively serving as transverse  framing, yet leaving the interior free of such structure.

framing, yet leaving the interior free of such structure.

In a system I call TSF for Tension Strip Framing, I often use UNI tapes (instead of more traditional internal wood framing) to limit deflection and add internal resistance against impact. This not only saves internal space and reduces the number of troublesome hard spots, but it’s also faster, more economical and easier to both

CF-UNI is particularly effective for creating very strong connections between parts, with tows of CF being laid in all the stress directions, before being covered by a bi-directional woven cloth to make a smooth covering surface.

Another cloth that’s also used more and more, is called BI-AXIAL. In this case, the fibers are laid in two directions at a significant angle to each other .. an angle that can be anywhere from say 60 to 90 degrees, with half that angle being from the main line of the cloth roll. So a 90 deg bi-axial, has strands at 45 deg one side of center and 45 deg to the other. Such cloths are available either interwoven (and therefore not very flat) OR are laid one over the other, with light cross stitching to hold them in place (see photo). Typically, both UNI and BI-AXIAL cloths are heavier than Bi-DIRECTIONAL (boat)

Another weave used for high strength where weight is less

Rovings are made from bundles of strands/fibers

Another bi-directional cloth that you will see advertised is ‘TWILL’ .. often with an added note ‘2x2’. This means that instead of each strand going under and over 1 strand, it goes under and over 2 … and in both directions, hence the '2x2' (see photo). This creates a less stable cloth that will deform more easily, making it more ideally suited to covering shapes that are 3 dimensional, with a hemisphere being a good example. It’s very seldom needed or used in boat

The other cloth I should mention is the classic MAT or CSM as it was called for Chopped Strand Mat. This cloth is made of short fibers (about 40-50mm long), blown down in totally random arrangement and held together with a bonding agent. This was once the basic material for all early fiberglass boatbuilding back in the 1950’s as it added bulk thickness fairly easily, was easy to apply, was the least expensive cloth and also offered ‘adequate’ strength in all directions without needing to do much calculating. While it still has the occasional use due to its ability to mold around any shape, boat building has since become more sophisticated, with composite cores and hi-tech weaves that allow the material to be more effective in dealing with the calculated loads, thereby reducing weight and achieving far more effective glass-to-resin ratios. With MAT, it’s a struggle to keep the resin below 60% of the layup, whereas with the new weaves and application methods, the resin part can be brought down to as low as 30-40%. This offers more strength and endurance, with lower weight. (But Mat is very effective fitting into difficult corners once the binder has been broken down and tapes of matt can work well over the inside of corner joints that will not be too highly stressed).

Something else worth mentioning here is that the binder for typical random MAT is one suitable for

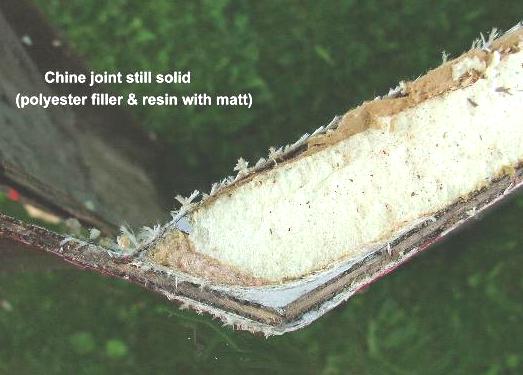

Although we seldom use mat anymore in modern boats, it does have some properties that are worth remembering. The random fiber arrangement bonds very well to a variety of surfaces and it does not peel off or delaminate from plywood like a sheet of regular cloth will. Many years ago I designed a 15ft double chine canoe for my

It was to be really inexpensive with a total (1979) budget of $100. We bought a couple of sheets of 3mm birch plywood (door veneer) for the skin and used ‘stitch & glue’ to hold the panels together until joints were made. We used CSM cut into 2.5” wide strips for the longitudinal joints inside and out, wetted out with polyester resin to cover the grey polyester car-body filler that we used to cove the joints and cover the wires.

The bottom was stiffened by bonding in ¾” polyurethane foam panels with contact cement and then glassing over on the inside with the whole boat then painted inside and out. I called the system

Finally, CSM is useful as the first layer when filling a Vee'd joint .. as when making a 'hybrid' scarph to join two pieces of plywood with a butt join using glass tapes. While such a joint can be made with a shallow Vee on both sides, I find it's easier to achieve on the boat itself if the inboard side has a thin butt strap (grain parallel to the plywood its joining and with beveled edges for the butt strap). Then the Vee is well ground out to finish the joint on the exterior, using several layers of different width tapes. This is where starting with say one or two narrow strips of random mat (CSM) can really help fill the Vee and make the initial bond, with bi-axial and bi-directional tapes over to complete the joint. (This is a system I recommend for the plywood side panels on my W22, and in this case, the interior butt strap - thinner than the main plywood - is also faired and glassed over with boat cloth to remove any hard transition).

Although this covers the most common weaves, there are also

Occasionally, one sees some fiberglass cloths that are ‘outside the norm’ and perhaps selling at discount. These are probably ‘left-overs’ from some special order for a particular weave for a custom job. Whether they are worth buying, depends on what the weave is and what your needs are. One particular weave I found a few years back was a 6oz cloth but with an open weave almost like a netting, with open squares of about 4mm (see photo).

So if you see something ‘On SALE’, try to get a small sample to see exactly what you are getting and if it fits your need, go for it. I also once bought a very lightweight 4oz UNI cloth, but that was not successful. It was so tightly woven that epoxy would not easily penetrate, so the cloth tended to float on top instead of bonding to the plywood. So test out a sample.

I had a similar experience with some 5 oz bi-directional

You will also find and need some cloth tapes. These are pre-woven into certain widths (typically 1” to 6”) and of different weights and weaves. The reference weight is still based on

There are also both structural and cosmetic finishing cloths so don’t get them mixed up. Buying a roll of CF Tow is always useful as this can be laid anywhere to reinforce a highly stressed area and then over-sheathed with

The use of KEVLAR is for abrasion resistance and as a lightweight fabric if under tension. As it is very weak in compression, it’s only effective on the tension side of any beam or surface and useless for say a mast where loads alternate. When exposed, KEVLAR will fluff up and be almost impossible to hold down for fairing, so frequently it's used with layer of glass over it to combat that difficulty. Kevlar is relatively light and tends to float on any pre-resin'd surface (as does Dynel), so special application techniques are needed to get/keep the air out and avoid excess resin. One way is to wet out the cloth on a separate table and then roll it up wet on a dowel or tube. Then unroll this on to your clean, dry surface and you will have 'just' enough resin to make the bond without enough to float the cloth. If a few spots are dry, its easy to stipple in a few grams of extra resin and roll it out. Kevlar is also notoriously hard to cut, but again, there are tricks. One is to add masking tape to the cutting line to stiffen it and then it can typically be cut by any heavy duty steel scissors.

Fiberglass fabric comes in two basic strength qualities. The standard one is called E-glass and the other is S-glass which is significantly stronger but far more expensive. The E was originally for ‘Electrical Grade’ when used for insulators, but you might want to remember it as ‘Economical’. The ‘S’ grade can be thought of as Super-glass, and there are now even S2 and S3 versions.

By the way,

You may find this YouTube adds some visuals to this discussion …

https://www.youtube.com/watch?v=ioj1YBm6bJY

While the above introduction is by no means ‘complete’, it should ease you through the first steps of familiarity with the various weaves and materials. Keep exploring and testing.

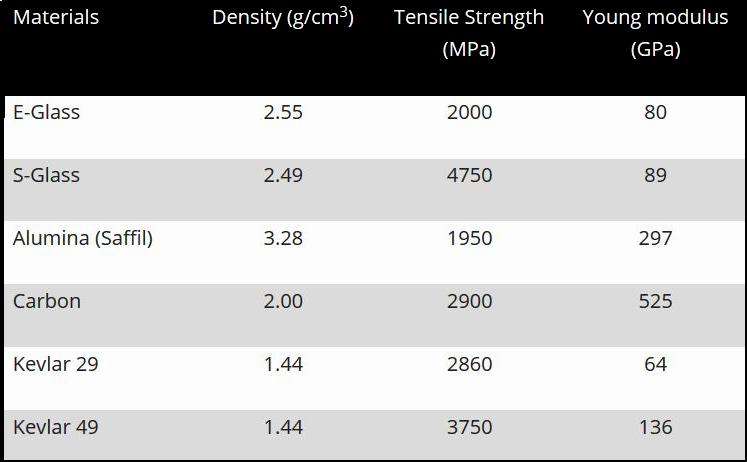

COMPARISON of Properties

Although this is only a general info article, it’s of interest to compare basic fiber qualities. It may surprise some to see that S2-glass is significantly stronger than certain carbon fibers and Kevlar – but is both heavier (Density) and less rigid (Youngs Modulus) than Carbon or Kevlar 49. And note that Kevlar is only 56% the weight of E-Glass. What is not shown here is the weak compressive strength of Kevlar that prevents it from being used far more broadly.

Although this is only a general info article, it’s of interest to compare basic fiber qualities. It may surprise some to see that S2-glass is significantly stronger than certain carbon fibers and Kevlar – but is both heavier (Density) and less rigid (Youngs Modulus) than Carbon or Kevlar 49. And note that Kevlar is only 56% the weight of E-Glass. What is not shown here is the weak compressive strength of Kevlar that prevents it from being used far more broadly.

(See 'Building the W17 Main Hull Part 1 'for more on using KEVLAR

Although S2-Glass is more than double the tensile strength of E-Glass and 10% stiffer, it’s also (at this time of writing) many times more expensive & also 73% heavier than Kevlar. But its high strength associated with high stretch without

For passing interest, the above table also includes Alumina-Saffil, a fiber used to reinforce aluminum and magnesium castings to create Fiber Reinforced Metals (FRM). For some 20 years now, such fiber has been used in some alloy engine parts (such as pistons, engine blocks and cylinder heads etc) … making them as strong as a cast iron product but much lighter. More info can be found here:

http://www.saffil.com/index/fibre_home/metal_matrix.aspx Mike 2018

"New articles, comments

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"